This article features first-ever photos taken from inside Anduril’s R&D facilities in Costa Mesa, California. All photos by Ryan Young.

On a Saturday afternoon in April 2024, I was on the rooftop pool deck of a Marriott hotel, setting up radar equipment aimed above the Hollywood Hills in Burbank, California. My five-year-old son, still damp from swimming, darted around as I calibrated the system.

“What are you doing?” he asked, touching the electronics with wet hands.

“Tracking … flying objects,” I said, carefully moving his hands away from the sensitive equipment. “It’s a special radar that will help our drones find targets better.”

Working on a thousand-dollar radar that could potentially transform a landmark missile platform during a father-son weekend was fairly typical in those days. The technology that my son wanted to touch, and which other poolside guests gawked at, was a throwback to the AGM-114 Hellfire missile system from the 1960s—a simple direction finder that could be guided by a ground system that paints targets with radio frequency (RF) instead of lasers. If we could get this to work, we could reduce the cost of our Roadrunner system—a reusable, twin-turbojet, vertical-takeoff-and-landing microfighter—by 30x.

Between trips to the pool and Chick-fil-A, I eventually managed to collect enough data to prove the concept worked: We could detect aircraft at 10 kilometers with a thousand-dollar sensor. It was the kind of breakthrough that could change how we approached reusable weapons and low-cost solutions for air defense—an ongoing R&D project I remain consumed by.

It wasn’t company-sanctioned work. I was officially on family time, having left Anduril as SVP of Engineering the month before to start a robotics company, Physical Intelligence (PI). Yet Anduril was never just a job; it was part of my identity. My badge still worked, I continued on in an emeritus role, and I still spent around 15 hours a week working with the engineering team I’d helped build.

When I joined Anduril in the fall of 2018, I was employee #20, the company was valued at $250 million, and we had lofty, but hypothetical, ambitions of reinventing the defense ecosystem. Less than six years later, the 4,000-person, $28 billion company has deployed 30-plus products with thousands of fielded systems, and changed the arc of American defense technology. It’s worth looking back now at those years of explosive growth, in order to give other founders, engineers, investors, operators, and everyone else a glimpse of what zero-to-one at Anduril was actually like.

Team member welding in Anduril’s R&D prototyping shop.

I’ve always been drawn to the kind of science that translates into strategic impact, and to problems too dangerous to ignore. After studying at MIT, I worked on flood disaster relief in Pakistan, then became a founding engineer at a biotech startup developing affordable genome sequencing technology. When the company was acquired, I left for Tesla, where I worked on projects from the Falcon wing doors in the Model X to electromechanical architectures, autopilot sensors and advanced technologies enabling future vehicle platforms. It was cutting-edge work with one of the most innovative companies in the world, and I was genuinely happy there.

A coffee in July 2018 with Anduril’s founder Palmer Luckey changed everything. What was supposed to be a quick 30-minute chat turned into a six-hour conversation that made it impossible for me to go back to Tesla. These were the days when supposedly bleeding-edge work in Silicon Valley was still largely dominated by consumer apps and services. By contrast, the picture of the world that Palmer drew kept me up at night.

While the threat from China wasn’t yet front-page news, Palmer and his team had already recognized the need for better defense technology to deter a great power conflict and to maintain American hegemony. They understood that America’s technological edge in defense was eroding, and that traditional defense contractors were too glacial and bureaucratic to meet the challenge—a culture I’d previously witnessed firsthand (and had forever sworn off) during an internship with an aerospace manufacturer.

I was struck by the Anduril team’s strategy of developing defense products on its own dime and selling them off-the-shelf, turning the traditional business model of defense contractors on its head. I was also impressed by their choice to build the company in Southern California, deliberately removed from Silicon Valley. My coffee with Palmer came only a few weeks after Google canceled Project Maven, which would have assisted the Department of Defense with AI-based drone-footage analysis. When I eventually told colleagues at Tesla that I was leaving to join a 20-person defense technology startup working out of a hangar near Santa Ana airport, they looked at me like I was insane.

Click here to subscribe to print for your office or home.

When I joined the company in September 2018, we worked out of a small building at 3000 Airway, then expanded into hangar B8, which was adjacent to a dog kennel at the Santa Ana airport. There was no heating or air conditioning, just incessant barking. I claimed a closet that received a little heat through proximity to another part of the building. That became my lab.

On my first day, I found myself back at MIT, on stage beside Palmer, explaining our vision to skeptical engineering students confused why anyone would work in the defense sector. By the end of that same week, I was on the southwest border installing one of our pilot systems, a surveillance tower. It wasn’t the polished product defense contractors typically wait to unveil—in fact, our first tower was literally a telephone pole with a gaming PC housed in a weatherproof box, a pan-tilt unit normally used as stage lighting, with spikes on it to prevent bird shit from blocking the sensors. A lot of it came from Home Depot.

That makeshift tower, which we built on our own dime to prove what was possible, helped intercept nearly 1,000 pounds of marijuana and led to dozens of drug trafficking arrests—ultimately earning us a pilot program with Customs and Border Protection. It was primitive, but it worked, and reflected our approach: get to a minimum viable demonstrator, something that creates end-to-end capability, then iterate ruthlessly. By then I understood that Anduril would be the fastest, most intense environment I’d ever experienced.

A few days each week, we’d pile into vehicles and drive to our test site in Apple Valley—a remote California desert location where temperatures reached 110 degrees on summer days, then dropped to 30 at night. We stayed in the cheapest hostel-like accommodations we could find and worked 16- to 18-hour days in complete isolation from distractions. We operated out of dusty trailers with minimal equipment. If something broke, we couldn’t just order a replacement part—someone had to drive 200 miles back to Santa Ana, rebuild the component, then drive 200 miles back.

Brian Schimpf, Anduril’s co-founder and CEO, functioned as our chief engineer, with an intuitive understanding of how every component fit together. Brian shaped our strategy and had a remarkable knack for pulling together engineering pieces and connecting them to business outcomes. When obstacles appeared, the other founders would come up with a strategy to unblock the engineering so Brian could focus on solving technical challenges—like the time co-founder and COO Matt Grimm chartered a plane in order to fly oversized batteries across the country for a critical demo.

Our first tower was literally a telephone pole with a gaming PC housed in a weatherproof box, a pan-tilt unit normally used as stage lighting, with spikes on it to prevent bird shit from blocking the sensors. A lot of it came from Home Depot.

Even in those early days, the company was single-minded and self-selecting. No one cared about meetings or performance management or building a well-rounded company. We lived and died by our ability to quickly fire a “tracer bullet” through the heart of each problem, illuminating a clear path to the full solution.

It was a bad day when we’d be testing a quadcopter drone and it would crash a couple of kilometers from the takeoff zone. That seemed to happen most often at night or on weekends at the Capistrano Test Site (CTS), an environmentally protected zone of beautiful rolling hills, where we had to recover every scattered bolt by hand. At 2am, we’d be searching in the middle of the cactus brush for a drone that had fallen out of the sky.

We came up with creative solutions, like gluing glow sticks to the “birds” (our word for drones) so we could see them in the dark, or putting beepers on them so we could hear where they landed.

Anduril’s first surveillance tower, with spikes to prevent birds from relieving themselves on the sensors and gaming PC.

Early radio frequency (RF) chamber, purchased on eBay.

Like diamonds, all great products are born from heat and pressure. Consider the Tesla Model 3: The battery engineers pushed for maximum energy density; the chassis team insisted on minimal weight and thickness; and the safety team required uncompromising crash resilience. Each group had conflicting demands, yet this friction ultimately yielded an exceptional battery pack—powerful, efficient, and safe. No stakeholder was completely satisfied, but through that creative rigor and tension, something extraordinary emerged.

The same was true at Anduril, where an additional layer of pressure came from the international political reality. America’s adversaries evolve tactics in weeks, and the company had to operate with that same urgency. We couldn’t deliver solutions in years—we needed to prototype, test, and deliver in months or weeks. Each product therefore had to embody our chief working principles: move fast with purpose; question everything; take ownership; keep it simple; hold high standards; and design with deployment in mind.

One of the first products I worked on was our counter-drone interceptor, Anvil. This was important because the US government had spent billions of dollars on counter-drone technology with limited success—in some cases, they were literally training falcons (real birds in this case) to take down drones, or using Patriot missiles costing millions of dollars to destroy $500 quadcopters. The inefficiency was absurd, but the problem was serious. In 2018, a rogue drone shut down London’s Gatwick Airport for two days, and they were being used on the battlefield more and more.

We had a simple idea: What if we just used a quadcopter to crash into another quadcopter? Our first prototype used an Intel RealSense camera to look up and fly into targets. The approach was primitive—if the target moved, we’d miss—but at a bake-off at White Sands Missile Range, our system successfully intercepted targets about 40% of the time, while competitors had single-digit success rates.

The government customer was in shock, but to us, a 40% hit rate was nothing to dine out on. They quickly deployed our solution as a stopgap overseas, which created pressure to improve, because the system could fall short in the field: the cameras and sensors couldn’t reliably detect targets due to glare or clouds, and our guidance system was too basic.

We had three months to stop the bleeding, and I spent my paternity leave developing a 3D radar system. I realized we could leverage the same radar technology used in self-driving cars, build an RF frontend with a non-uniform antenna, and create our own algorithms for terminal guidance instead of collision avoidance.

In three months, we went from a 40% kill probability to knocking out 35 of 35 targets. There wasn’t a quadcopter you could throw at our mechanical bird that it couldn’t take out. We even hired one of the top First Person View (FPV) drone pilots to try to evade our system. Anvil caught the drone every time.

As Elon would often say at Tesla, “If the schedule is long, it’s wrong; if it’s tight, it’s right.” Speed was our weapon. Even our recruitment process reflected this: We’d openly talk to candidates from defense contractors and show them around our facilities, confident that we were moving faster.

“Our first prototype used an Intel RealSense camera to look up and fly into targets. The approach was primitive—if the target moved, we’d miss—but at a bake-off at White Sands Missile Range, our system successfully intercepted targets about 40% of the time.” Anvil V1.

Repairing the bistatic radar seeker with a soldering iron in the electrical engineering R&D lab.

We paired speed with another key principle: question everything. This meant engineering from first principles—breaking down every problem into physics, math, and operational reality, then building solutions from there.

In 2019, the US Air Force wanted to explore new solutions for detecting low-altitude cruise missiles—a critical capability with threats from Russia and China that could penetrate our borders. The official requirements for the Advanced Battle Management System (ABMS) program called for a radar with high azimuth and elevation accuracy and full hemispherical coverage, which would mean multimillion-dollar systems.

But no air defense radar manufacturer wanted to sell to us—some because we were a small no-name company, others because they wanted to capture the full value of delivering their own systems, still others because they saw Anduril as a potential future competitor. We needed to create our own solution, but traditional radar development takes years.

Instead of taking the Air Force’s brief at face value, we asked: “Why do they need hemispherical coverage? What’s the actual threat?” The primary concern was low-altitude cruise missiles coming across unprotected territory, which meant we only needed to cover the first few degrees above the horizon, not the entire sky.

We modified a $5,000 commercial boating radar—the spinning “candy bar” type you see on fishing vessels. Boat radars are designed to detect small objects far away on water, but not in the air. By modifying the waveguide assembly to create a narrower beam, we concentrated more energy in a specific direction and extended the range by about 10x.

When we showed up to the bake-off with our cheap modified boat radar mounted on a rickety welded truck, competing against traditional defense contractors with multimillion-dollar systems the size of a shipping container optimized for 360-degree hemisphere coverage, the other attendees laughed.

Yet we won. We understood what the customer needed to accomplish, but mostly ignored what they thought they wanted in their requirements. Our system could be scaled along any border as a true cruise missile detection network at a cost that was orders of magnitude lower than traditional solutions.

Inner guts of a tower assembly.

The author flying the Anvil V3.9.

Every project at Anduril had a directly responsible individual (DRI)—a single owner accountable for the outcome from end to end. Sometimes ownership meant taking extraordinary measures when the stakes were high.

One of the most dramatic examples arose at a critical test for a US defense customer of our V2P interceptor drone—a quadcopter that could fly at 150 miles per hour and intercept other drones with impressive accuracy. This was a billion-dollar contract opportunity that could transform Anduril from a border protection startup into a serious defense company.

V2P was an evolution of our Anvil system. After successfully developing Anvil to intercept small quadcopters, we discovered a much bigger threat emerging: larger Group Two and Group Three drones. The former are often used for intelligence reconnaissance and surveillance missions, and the latter with larger payloads and longer ranges. Countries like Iran were developing the Shahed series—massive drones that could carry substantial explosive payloads and fly kamikaze-style into bases.

Anvil was already successful, but it wasn’t designed for these larger targets. It needed a complete overhaul: more speed, better guidance, and enhanced durability.

We lived and died by our ability to quickly fire a “tracer bullet” through the heart of each problem, illuminating a clear path to the full solution.

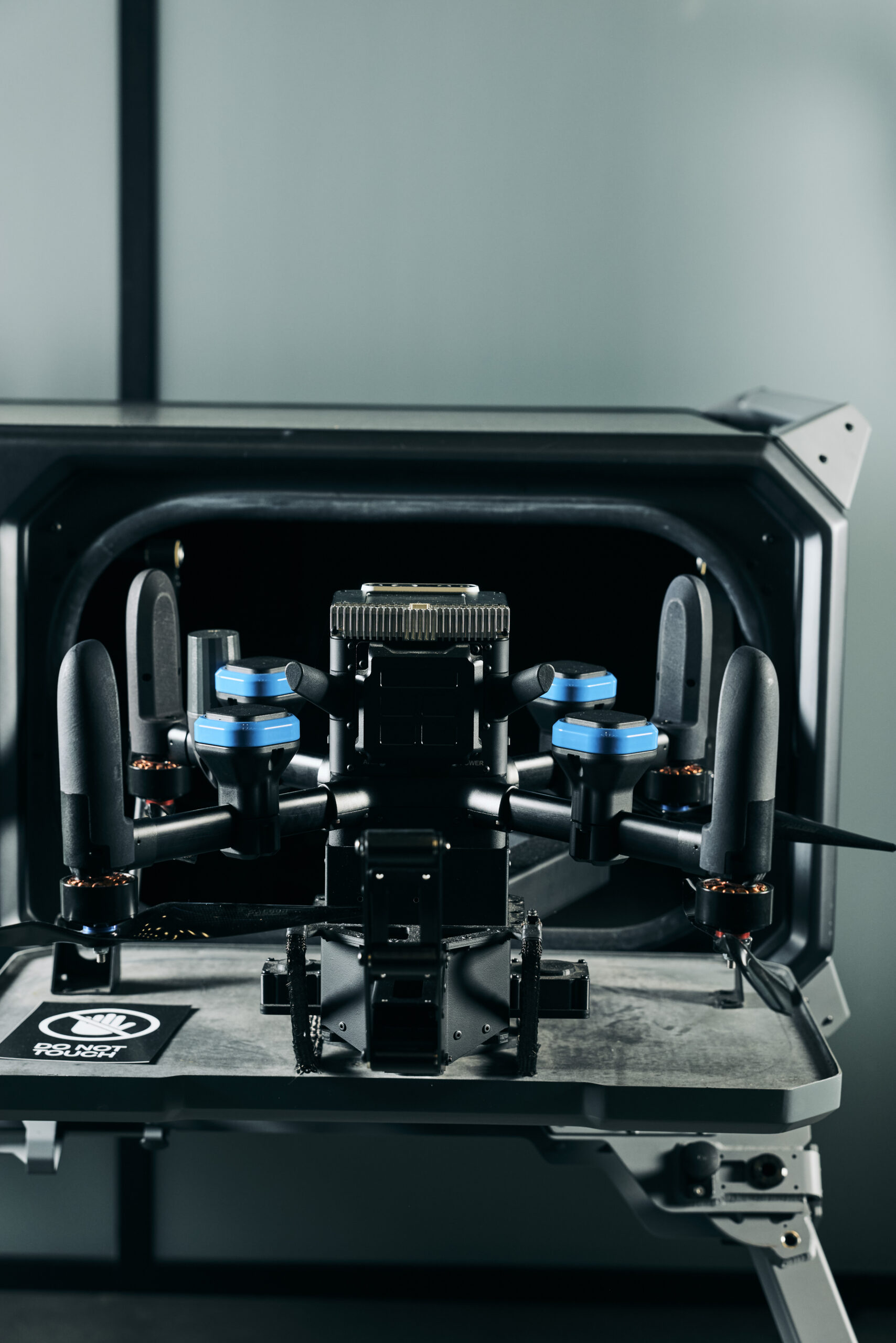

Over three and a half months, we developed the V2P. We redesigned the propellers, motors, and the entire power architecture, which pushed the boundaries of what a small drone could do.

The result was unheard-of: a 5.2 kilogram vehicle that could achieve a speed of 147 miles per hour. (The world-record quadcopter at the time weighed 800 grams and did 173 mph). More impressively, it maintained sub-degree accuracy on pitch, roll, and yaw, even at steep angles of attack, where quadrotor dynamics become extremely challenging.

As a US defense customer’s Systems Integration Partner (SIP) competition approached, we needed to build 50 drones. One of our lead engineers from the test team and his co-worker came in on a weekend and built 28 complete vehicles in a single day—a feat that would have taken weeks through conventional processes. In total, they built 53 vehicles in 14 days, test-flying each one three times while I analyzed all the flight logs in real time. When we arrived at the competition, our competitors showed up with elaborate, expensive systems that had been years in development. Our V2P interceptor dominated the event. It destroyed 30 targets with extra interceptors to spare.

The highlight came on the evening before the last day of the bake-off, when US government officials asked if we could take down a far bigger Group Three aircraft—much larger than our system was designed for. With our existing approach, the V2P would simply bounce off such a large target. But we had a potential solution: radar firmware that could identify propellers through micro-Doppler signature and target them specifically. The night before the upcoming test round, we needed to finish writing the updated firmware and flash all of our drones with it.

At 3am, the same lead engineer who built 53 vehicles in two weeks went down to the hotel room where the drones were stored and proceeded to disassemble 18 birds. He took apart each radar, separated the processor and RF boards, hooked them up to his computer, flashed them with the new firmware, verified the changes, and reassembled everything. At 7am, he casually walked out as if he’d just woken up like everyone else, as the competing teams came down the elevators.

On the last day of the bake-off, our modified V2P took out the Group Three target on the first attempt, hitting it directly through the propeller. The entire room erupted in celebration.

That win was the cherry on top of a 200-person effort that ultimately secured a billion-dollar program of record for Anduril, transforming the company’s trajectory. It also exemplified the level of ownership we cultivated in our engineers—people who felt in their bones that they owned the outcome, and therefore cared so deeply about it that they didn’t blink at doing the kind of dirty work that their counterparts in other companies might consider drudgery.

This kind of approach is never without risk. But in our environment, we gave people agency and trusted their judgment. When a single engineer saw a 50/50 chance of success versus the near-zero probability with the original firmware, he made a call that changed Anduril’s future.

Team member building a Bolt for development testing.

Click here to subscribe to print for your office or home.

In engineering, simplicity is strength. At Anduril, we continuously asked what we could eliminate or simplify.

Consider the challenge of defending vast territories against cruise missiles. Conventional systems, like Patriot PAC-3 and NASAMS batteries, typically cost millions of dollars per installation. So we asked ourselves a simple question: What if we could create a forcefield of low-cost drones to intercept cruise missiles worth millions?

The concept seemed absurd at first, even to our team—the overmatch appeared too extreme. But we stripped the problem again to its fundamentals. Cruise missiles are fast, but they follow predictable flight paths. If we could accurately determine that flight path using two ground-based IR passive sensors (what we called Wide-Area Infrared System for Persistent Surveillance, or WISPs), we wouldn’t need expensive targeting systems on the interceptor itself.

We modified our Anvil drone to carry no sensors at all—the drone would simply position itself in the projected path of the incoming missile, aligning with where the missile would pierce our virtual “force field.” Despite the initial skepticism, we demonstrated the concept successfully, destroying a target that could fly an order of magnitude faster than our interceptor.

The beauty of this solution wasn’t just its low cost, but its elegance. We didn’t need to match speed with speed or complexity with complexity. We found the simplest possible point at which to intervene and disrupt the threat.

We applied this thinking to all our products, and constantly fought against feature creep. Most product managers naturally want to add capabilities—one after the next after the next. But we ruthlessly focused on the 20% of features that delivered 80% of the value, and made those exceptional.

A prototype compressor for Roadrunner turbojet development.

Team member utilizing a 5-Axis DMG machine to make challenging parts.

Yet there’s a line between scrappy and crappy. At an all-hands meeting a while back, one of our team members asked, “Why don’t we just build perfect products?” The answer reflected our core philosophy: We had an ethical obligation to get the best solutions into warfighters’ hands quickly. We could build one or two gold-plated systems over the course of years, or we could deliver 10 near-perfect solutions that actually make it to the field in a battle-relevant timeframe.

We were scrappy to the core, but we also had a very clear understanding of what “deployability” meant for each system. We were uncompromising about those standards while tolerating rough edges elsewhere. A disciplined approach to trade-offs allowed us to deliver capabilities that competitors with 10 times our resources couldn’t match. The key was attention to detail. Teams without a painfully clear understanding of what’s important have a bias toward frills, whereas we went after the aspects that delivered the most value to the warfighter—avoiding the classic mistake that sales-led organizations often make by building pretty products that fall short in functionality or usability.

To take one example, when we learned the Marine Corps was seeking a new loitering munition, we initially didn’t want to compete. The thinking was that a different company specializing in thermal imaging cameras and sensors had been working on this project for five years, and Anduril would simply waste millions of dollars trying to beat them.

Yet the opportunity for a competitive edge remained. Quadcopters usually flew slowly into targets horizontally and could be seen coming from far away. What we needed was a drone that could dive with such blistering speed that by the time you heard its scream, it was already too late … If we could come up with a game-changing new capability for top-down kills that would be much harder to anticipate, we could win.

I asked Raichelle Aniceto, my chief of staff, to procure the competitor’s drone, and within days, we had one completely disassembled in our lab. We hot-glued the components onto a trifold board using her wedding invitation kit. What appeared to be a science fair display nevertheless clearly demonstrated how each component was not only suboptimal, but dependent on multi-tiered foreign supply chains—and that we could build something lighter, faster, easier to manufacture, and more reliable, while de-risking tangled Chinese supply chains.

Like diamonds, all great products are born from heat and pressure.

But there was a catch—the Marines expected a product, not a proposal, and we had nothing more than a concept. We went a week without sleep to create high-performance renders, building life-like mockups, and drafting a technical proposal for a drone that didn’t yet exist.

The proposal was submitted 60 seconds before the deadline. We won the first phase, but now we had to actually build what we’d promised.

This became Bolt—a loitering munition that could precisely target ground vehicles. I saw it as a weekend project at first: take our existing drone platform, retrofit it with a vision seeker, and have it crash into ground targets instead of aerial ones. We created a quick demonstration video for a proposal and were one of the few companies down-selected.

As the project progressed and the stakes escalated, we learned that what worked for aerial targets wouldn’t work for ground targets. The team tried to apply the same guidance approach that worked for Anvil, but when diving at steep angles toward the ground, the drones kept missing by several meters.

During a critical customer demonstration, our bird completely missed its target. The room went silent. We knew we were at risk of losing a half-billion-dollar program milestone if we couldn’t fix Bolt quickly.

The engineering team tried applying more aggressive corrections, but the misses only grew wider. It turned out there was a fundamental issue: When a quadcopter dives downward faster than its propellers can “bite” through the air, the propellers act as air brakes, inverting the effect of guidance commands. We needed to completely reverse their guidance commands when crossing this threshold.

That weekend, I developed an entirely new guidance approach we called “Dive,” which allowed the drone to fall along a target vector with precise lateral corrections. Along with optimizing the propellers for inflow velocity with dynamic throttle margin, the problem was solved.

Later on, when preparing for a demonstration with a four-star general, another issue emerged: The airframe was vibrating and we were losing attitude control. The team drove the drone (with no lethal payload on it, of course) from Southern California to my home in Los Altos in the middle of the night. The next day was the baby shower for my second child, and we spent the hours and minutes before the guests arrived tuning the drone in my backyard.

The ferocious commitment from our team paid off again: The Marine Corps down-selected Bolt for its Organic Precision Fires-Light (OPF-L) program.

“The ferocious commitment from our team paid off again: The Marine Corps down-selected Bolt for its Organic Precision Fires-Light (OPF-L) program.”

It was never enough to create solutions that worked in the lab. Each one had to work reliably in the field, at scale, and at a cost that made sense.

This was part of Anduril’s secret sauce, and antithetical to how traditional defense contractors operate. The defense primes typically optimize for high-margin, low-volume production with expensive maintenance contracts. Anduril brought Silicon Valley’s mindset of scalable technology to defense—solutions that could be mass-produced and widely deployed.

When designing hardware, we broke the product development process into three distinct stages. In the conceptual phase, the most important metric was lead time—how quickly we could get the components needed to build a prototype. In the new product introduction phase, when building 10 to 100 units, we focused on ramp time—how quickly we could work with vendors to reach the rates required for a pilot. In the third stage, full-rate production, the focus shifted to scrap rate and cycle time.

Traditional defense programs often fail because they create exotic systems that are too hard to produce or too expensive to deploy at scale. We were determined not to make that mistake.

By designing with scale in mind from day one, we aimed to create a virtuous cycle: our products could be deployed more widely because they were affordable, which generated more data and experience, which improved the next generation of products.

These core principles guided our product development. But principles alone aren’t enough. To apply them consistently across hundreds of engineers and dozens of products, we needed to design an organization that could sustain this approach at scale.

Electrical test rack with a new board.

As we approached 60 employees, it became impossible for everyone to report to Brian. What began as my leadership of a handful of electrical engineers quickly expanded to 75 people, then to all hardware engineering, and ultimately to all product engineering—electrical, mechanical, and embedded systems combined. When I became SVP of Engineering in June 2022, I had 164 people in my department. By the time I left in March 2024, it had grown to 550 engineers working on 30 products across 15 different families.

Building a high-performance organization was as important as solving technical problems. Throughout my time, I had to maintain this dual identity—an engineer on the frontlines driving design and development, and also a leader responsible for creating the organizational structure that would enable others to do the same. I needed to build a leadership team that could own full lifecycle product development and deliver world-class systems at the pace and precision demanded by our mission. Every hire was made with this blueprint in mind.

The first priority was to anchor the organization with deep technical credibility. “Badass engineers want to work for badass engineers,” as the saying goes—the best will only work for leaders they can learn from and respect technically. We needed to avoid the common mistake made by organizations which fail by promoting or hiring managers without the technical skills to understand problems, build strong teams, or avoid making flawed engineering decisions.

For the electrical team, we wanted to position ourselves at the leading edge of avionics design. I recruited Shaun Donovan, a veteran of General Atomics and an early employee at Anduril, who had been involved in nearly every major electrical design to date. His mandate was clear: take hard-won lessons from legacy systems, and build the next generation of electrical architecture from first principles. On the mechanical side, we needed a leader deeply experienced in rapid prototyping and fabrication; someone who could translate ambitious concepts into functional hardware quickly and effectively. That was Matt Zipfel, whose career at SpaceX was defined by turning bold mechanical ideas into working prototypes under intense timelines.

With the core engineering leadership in place, the next critical step was embedding product thinking across the organization and developing a scalable product platform. We needed product leaders who could unify technical execution with the production rigor needed to scale. I brought over Danish Tejani, Anduril’s first hardware product manager and a former NPI lead at Tesla, to help build our product development function.

As the team matured and the product portfolio expanded, it became clear that maintaining alignment with the defense customer was both a strategic imperative and a growing risk. Many of our new hires came from non-defense industries, and while that brought valuable innovation, it also introduced a potential gap in mission understanding. To close that gap, we hired Joe Bayer, a former GA program executive and F18 pilot. His deep domain knowledge and firsthand understanding of defense customers allowed us to stay laser-focused on delivering solutions that mattered.

The final piece of the leadership architecture was operational scalability. By this point, we had grown to hundreds of engineers across dozens of teams. We needed a chief of staff who could partner with me to build and run the engineering organization, without losing the technical context that made us successful. It’s common practice to hire Jared from Silicon Valley types, but I needed someone who could communicate with engineers on their level and play the role of a technical leader. That was Raichelle Aniceto—an MIT-trained aerospace engineer who led Relativity Space’s ambitious Terran R rocket program.

Test racks for electrical assemblies in the R&D building’s electrical engineering lab.

Dev space in the R&D building’s electrical engineering lab.

Anduril is “an amusement park for engineers,” as I once remarked, because we worked on such diverse and challenging technologies. But behind the thrill and excitement had to be a carefully designed system that could turn ambitious ideas into deployable products. As we grew from a handful of engineers to over 500, maintaining our speed and innovation became increasingly challenging. Traditional organizational models wouldn’t work—dedicated teams for each product would have required thousands of engineers and created silos that slowed innovation. We needed something different.

We rebranded our engineering organization as “Product Engineering” to make our purpose clear: delivering products that meet customer needs. We then consolidated scattered teams into a cohesive group with three clear frameworks: products, core technologies, and key capabilities.

Products were our mission-focused integrated systems. Core technologies were our standardized building blocks—our LEGO pieces—that could be rapidly assembled into new products. Instead of starting each drone from scratch, we created reusable components like flight computers and propulsion systems. Key capabilities were our internal engineering services, like a machine shop that could transform digital concepts into physical prototypes within hours, or teams that could “shake, bake, and shock” components to ensure reliability.

What made this work was our matrix organization. Instead of creating dedicated teams for each product, we built functional organizations (across electrical, mechanical, and embedded systems) with deep expertise that could surge resources toward critical projects when needed. When we began developing Roadrunner, we pulled engineers from electrical and mechanical pools for intensive development, then shifted them to other projects when those phases ended.

The results were unprecedented in hardware: In early 2023, fewer than 200 people were responsible for over 25 different products, some of which were deployed across the world in the order of thousands.

We maintained integrated product teams where specialized expertise was required, like our Electronic Warfare group led by Sam El-Akkad, with deep RF and signal processing expertise. Or the Imaging team led by Bill Ross, with expertise in developing sensors down to the pixel-level silicon design. We also established product architects who were responsible for trade studies and system-level decisions—engineers who had proven themselves technically and could now lead cross-functional efforts.

With this foundation, we maintained small, focused teams while leveraging the broader ecosystem around them. But structure alone wasn’t enough—achieving this level of performance required recruiting the right people and building strong leadership capable of operating in a dynamic environment.

The author setting up a Pulsar, Anduril’s electronic warfare product, in a RF anechoic chamber.

The leadership approach at Anduril centered on a few core principles.

First, we prioritized relentlessly through a daily red-light/green-light system based on the Objectives and Key Results (OKRs) we set. Every product and project had clear metrics that we reviewed constantly. When something showed red, we’d immediately assemble the team to identify root causes. This consumed 60–70% of my time—figuring out the biggest obstacles and eliminating them alongside the team. I was notorious for being chronically late to scheduled meetings because I wouldn’t cut short work on critical problems.

Second, we maintained technical credibility through hands-on involvement. By day, I’d handle the corporate aspects—meeting with leaders across the company to drive product and technology development, and continuing a constant discussion about what was slowing us down, what was blocked, and what was broken. But after 5pm, my engineering work began. I’d return to the building at 7:30pm after dinner and wander the labs until the early hours, sitting with teams debugging problems. I’d whiteboard calculations, write Python scripts, and sometimes even solve structural dynamics questions. Engineers knew leadership understood their challenges at a fundamental level because we were there doing the work with them.

Third, many of us deliberately stayed out of the spotlight. If you look through photos of our major victories in those days, you won’t find me in them. This wasn’t false modesty; it was strategic. I wanted teams to own their achievements completely. By giving them full credit, they grew more confident and capable for the next challenge.

The results were unprecedented in hardware: In early 2023, fewer than 200 people were responsible for over 25 different products, some of which were deployed across the world in the order of thousands.

Underlying these principles was a fundamental belief: I work for my team. These 550 engineers were dedicating the best years of their careers to Anduril, and I felt responsible for making those years meaningful. My job was to harness the unique superpowers of each individual and create an environment where they could thrive.

This philosophy has to start at the top, and the impact of this approach, exemplified by Brian, cascaded through our organization. When leaders instead prioritize expanding their scope and influence over developing their teams, they create a vacuum that attracts similar self-interested leaders. The result is inevitable: layers of political fiefdoms that don’t value winning at an outcome level and don’t care about their people.

We elevated our approach into the management structure by promoting engineers who had earned respect through technical excellence, and creating a “scaffolding” system to support these technical leaders as they developed management skills.

The latest Anvil, equipped with energetics and Launch Box.

Backside of the bistatic seeker.

When it came to recruitment, we obsessed over what I called “the highest density and intensity of talent.” While talent density is a common concept, we focused equally on how to leverage a team’s capabilities through the environment we created. As Steve Jobs illustrated with his rock tumbler story, ordinary rocks become polished gems through friction against each other—just as talented teams polish each other through productive conflict to create something exceptional.

Our hiring approach was uncompromising. We installed “bar raisers” on interview panels—people who would reject candidates unless they were exceptional. I personally spent about 20% of my time on recruiting.

Even when scaling to 30–40 hires monthly, I interviewed most engineering candidates. I built Python dashboards to analyze our talent sources and maintained a LinkedIn Recruiter account. We expanded geographically, opening offices strategically to access new talent pools when my personal network was completely depleted.

We sought engineers who combined technical excellence with passion for our defense mission. We particularly valued former startup founders for their demonstrated agency and self-motivation.

Our performance management philosophy sat between two extremes: Elon’s approach of firing anyone on the left side of the performance curve versus Jensen Huang’s philosophy of trying to uplevel everyone. Elon believed that if you had five apples and one might be rotten, you have to throw out the whole batch. It’s a ruthless but logical view—bad apples can spoil the bunch. My approach aimed to be pragmatic—we maintained annual 10% attrition targets, but focused on clear expectations and respectful transitions.

We created a quarterly performance coaching program that identified the bottom 10% who needed support. We established clear OKRs so everyone understood their metrics for success. With transparent expectations, underperforming engineers often recognized on their own when they weren’t the right fit, leading to more respectful separations. This avoided the toxic alternative, common in other companies, where managers undermine struggling employees behind their backs rather than addressing issues directly.

Preventing organizational bloat proved equally critical. B-players who don’t understand product requirements tend to inflate headcount needs. When business lines claimed they needed 50 people for a project, we evaluated the engineering requirements and often found half were unnecessary. Our hiring estimates typically ran at half of what stakeholders requested and a third of industry standards. I reviewed every engineering hiring proposal personally, rejecting many while we still grew rapidly.

Building this culture was like coding our organizational DNA—you need the right sequences at the start. The legendary stories from Anduril’s early days became the foundational code, continuously retold and refreshed with new chapters, embedding traits that transformed new engineers into problem-solvers capable of the impossible. When I became responsible for new teams, engineers would approach me saying, “We’ve heard so many stories about what it was like at the beginning.” These stories weren’t just entertainment; they transmitted our values and showed what was possible. As our team grew by over 2,500%, these legends ensured that each new hire understood what made us different.

Thermal imager with a 900mm lens, in the R&D building’s dev test lab.

Throughout my career, I’d worked on cutting-edge hardware systems—drones, missiles, autonomous vehicles—that could theoretically perform any task, but in practice were often constrained by limited autonomy and human-guided control. Despite extraordinary advances in robotic hardware, the foundational intelligence to power these systems lags far behind. Most autonomous robots remain essentially puppets on strings, awaiting human instruction or executing elaborately choreographed behaviors.

In February 2024, I’d been approached about advising a robotics startup and called Brian to discuss it. We talked about physical intelligence and how, while AI companies everywhere were chasing language models and reasoning, half of the world’s GDP was generated by physical labor—yet no one had cracked the foundational model for robots to function effectively in the real world.

Brian listened carefully, then said something that will stay with me forever: “I’ve always seen you as a founder.”

For me, this wasn’t just encouragement—it was perspective from someone who had followed the same path, moving from leading engineering at Palantir to co-founding Anduril. Brian ultimately supported my growing belief that building a universal intelligence to unlock the limitless capabilities of robotic hardware—and fundamentally reshape humanity’s experience of physical labor—was an opportunity I couldn’t pass up.

I thought then of my son, and the innumerable times he accompanied me, often at strange hours and with curious equipment in tow, to desert test sites, landing strips, and hotel rooftops. The best problems, I’ve always told him, are the ones everyone else avoids, until they become impossible to ignore. When he tells me he wants to build things like me when he grows up, I feel the weight of the work I did at Anduril, and what I still have left to do.

In May 2024, I left the company as a full-time employee to co-found Physical Intelligence (PI). PI is now building the universal intelligence model that can finally close the gap: a single, powerful “brain” capable of bringing genuine autonomy to every physically actuated device, from drones and industrial robots to household appliances. Solving this problem means more than a technological breakthrough: it’s about fundamentally redefining humanity’s relationship with physical labor, enabling a productivity revolution on the scale of industrialization itself.

The point is that Anduril’s own mission is so impactful, and meant so much to me, that I couldn’t have left it for any other mission short of PI’s. Still, the decision to leave wasn’t easy. I’d helped build a team of 550 extraordinary engineers who had become family. But the culture of ownership we’d created meant they didn’t need me anymore.

Adnan Esmail is the co-founder of Physical Intelligence and Emeritus SVP Engineering at Anduril.